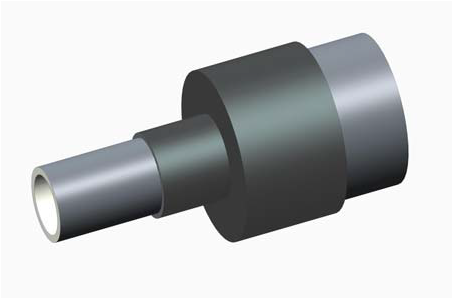

Casing End Seal

PRODUCT BRIEF

Casing End Seal is a heat-shrinkable end cap used for sealing the annular space between casing pipe and carrier pipe at casing ends so as to prevent ingress of moisture, water and contaminants. This waterproof cap is mainly used for anti-corrosion pipe insulation, which can effectively prevent the ends of the casing pipe from insulation damage or leakage, thus ensuring the pipeline corrosion performance and extend the life of pipelines.

MATERIAL SPECIFICATION

Casing End Seals are made of heat shrink high density radiation cross-linked polyethylene with its inner surface being molded with composite layer of specialty adhesive having a melt point suitable for the pipeline service temperature and ambient temperatures foreseen during construction. The materials used are resistant to heat, cold, vibration, impact, abrasion, corrosive fluids, disbonding, organic and bio-deterioration.

PRODUCT FEATURES

♦ Casing End Seal are designed to provide a watertight seal and prevent water access to the exposed insulation at the weld joint area. Upon application of heat, it shrinks to conform to the profile of the insulated pipe, while the sealant simultaneously “melts” to bond to the jacket pipe and the service pipe. To ensure overall protection of the insulating foam, it should be used on both pipe ends.

♦ End Seals are designed to be made flexible to cater the expansion and contraction of carrier and casing pipes as well as tolerate both angular and concentric misalignment of casing pipe without losing the sealing efficiency.

♦ End Seals are quick and easy to install and also prevents long damage and decay and hence saves repair & maintenance costs.

♦ Hot melt adhesive coating has self healing powers, high mechanical strength, heat resistance, corrosion resistance, cracking resistance, chemical resistance, resistance to environmental stress and resistance to water vapor permeability giving Casing End Seals a long service life.